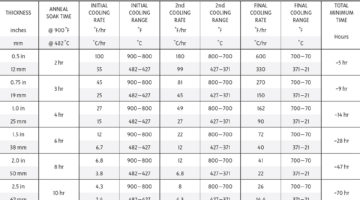

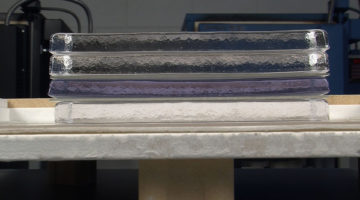

Recommended Annealing Cycle for Bullseye Glass L206

This 20-minute presentation focuses on the theory and process of getting the stress out of fused glass work and acts as an introduction to the new annealing cycle recommended by Bullseye.

This 20-minute presentation focuses on the theory and process of getting the stress out of fused glass work and acts as an introduction to the new annealing cycle recommended by Bullseye.

Here, we cover strategies for successfully reheating pre-fired work, the cumulative effect of heatwork on glass, how to anneal works that have been fired multiple times, as well as some special considerations.

In this lesson, you'll learn about design, setup, and firing considerations for kilncarving billets, as well as some variations.

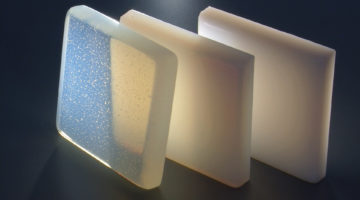

In this lesson, we'll use a similar method to "Working Deep", making a thick slab of glass for a small tabletop with a combination of sheet glass and billets for rapid assembly.

In this lesson you will learn how to prepare a wax model, how to make a two-layered refractory mold, how to steam the wax out of the mold, and successfully cool and clean the piece.

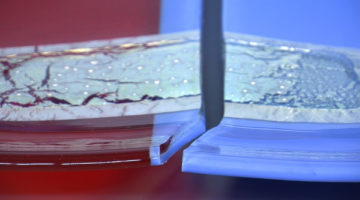

Box casting is a great way to create a reverse-relief, cast-glass object with exceptional clarity. This process is ideal for producing multiple editions of a piece.

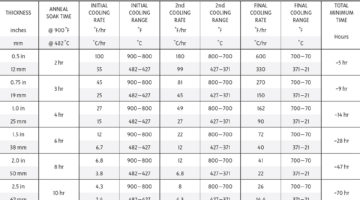

In this lesson you will learn how to create individual design layers, lay up a block to control bubbles and minimize coldworking, and considerations for damming, firing, and finishing the work.

In this lesson you will learn how glass flow can be controlled to spectacular effect.

This lesson covers two of the most common causes of a piece breaking: thermal shock and improper annealing.

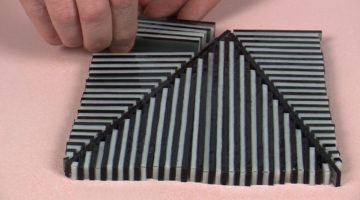

In this lesson you will learn tips for cutting and composing with glass strips, as well as some special effects you can achieve with on-edge construction.

This lesson provides basic instructions for making a thick-walled kilnformed glass container.

In this lesson, you will learn considerations for preparing a model, tips for making an open-faced mold and calculating the amount of glass needed to fill it.